The pneumatic suction and blowing pumps (PA/PS) are the pride of the Graphic Division, a division created from the experience of Vuototecnica, entirely dedicated to the graphic design and printing sector and a leader from engineering to service, able to offer innovative and advantageous technological solutions from all standpoints: performance, reliability, durability and operational economy.

The pneumatic suction and blowing pumps (PA/PS) are the pride of the Graphic Division, a division created from the experience of Vuototecnica, entirely dedicated to the graphic design and printing sector and a leader from engineering to service, able to offer innovative and advantageous technological solutions from all standpoints: performance, reliability, durability and operational economy.

They represent the absolute best of the new generation of multiple-ejector pneumatic pumps (multi-stage); they are able to suction or blow as needed and represent a real evolution compared to conventional electric, suction/discharge, and rotary vane pumps.

Thanks to the new generation of ejectors, the PA / PS pumps have an excellent ratio between and the quantity of air consumed and of that suctioned (or blown) and all this while benefiting operational consumption. However, the list of advantages of these products is still long:

- They ensure the ability to adjust the vacuum level (or pressure level) and the capacity, based simply on the air supply pressure. Depending on the air supply pressure, the pumps can be controlled with proportional valves for compressed air, limiting consumption to the minimum necessary, depending on the weight and porosity of the paper and cardboard in the printing machine.

- They are surprisingly quiet (60-65dB)

- The total absence of heat benefits the work environment.

- They only blow fresh air, free of impurities, condensate and oil vapours, between the pages to be separated.

- Reduced electrostatic charges generated by the hot air blown by conventional electric pumps.

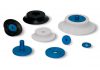

- The use of selected, hi-tech, latest generation materials has made it possible to reduce the weight of these technological jewels and to install them directly on the machine.

- Minimal maintenance required; just a simple cleaning of the suction and blowing filters.

- 5 YEAR GUARANTEE

Here are some of the main types of printing machines in which PA / PS pneumatic pumps are used:

Sheet feeders: To lift the sheets using vacuum suction cups and separate them with a puff of air.

Sheet stoppers: System for stopping the sheets printed in the output area and to stack them quickly, using suction bars.

Benders: For bending paper during operations that require both suction and blowing.

Binders and gluers: For binding books or brochures via independent work stations equipped with suction and blowing systems.

These are just some of the potential uses of PA / PS pumps in the paper industry, but Vuototecnica’s Graphic Division is ready to meet the needs of each individual printer who intends to increase their productivity and improve their work environment.