As you already know, regular readers of our blog, Octopus customization pushed to the maximum point thanks to the realization of gripping hands using a 3D printer.

We already saw a similar application in the post dedicated to CO-BOT by Universal Robot. (If you missed it you can find it here.)

In the video below, you can see in action another robot with multi-sided gripping hand and different suction plans depending on the objects to be taken and moved.

Please, notice the precision and solidity of different gripping: from food packaging, to cardboards, passing through porous sheets, up to the aluminum cans and to liquid-filled blisters. All packaging formats can be moved thanks to Vuototecnica Octopus.

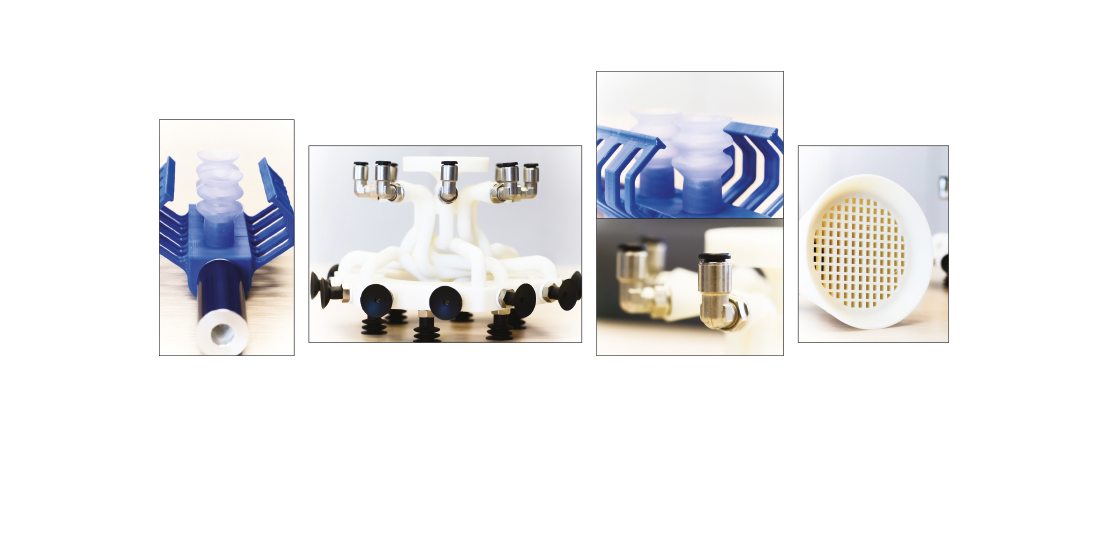

The gripping surfaces can be in foam rubber, can mount rows of suction cups, Bernoulli systems, without contact, or be customized in 3D.

Thanks to 3D printing, in particular, customers’ needs are treated case-by-case, with custom-designed gripping heads to accommodate the shape of the object, winding and holding it. The gripping hands are made of ABS and so they can be resistant and light at the same time.

In this specific case, the source of vacuum generation is external to the gripping hand, but it is possible, according to the space requirements, to integrate pneumatic ejectors directly inside.

Please, contact Vuototecnica designers to request your personalization on www.vuototecnica.net