Showing the applications of Vuototecnica products in video is sometimes useful more than a thousand technical words, so we like to comment here on the blog videos of our end users.

Here we deal with the processing of wood panels with CNC machines:

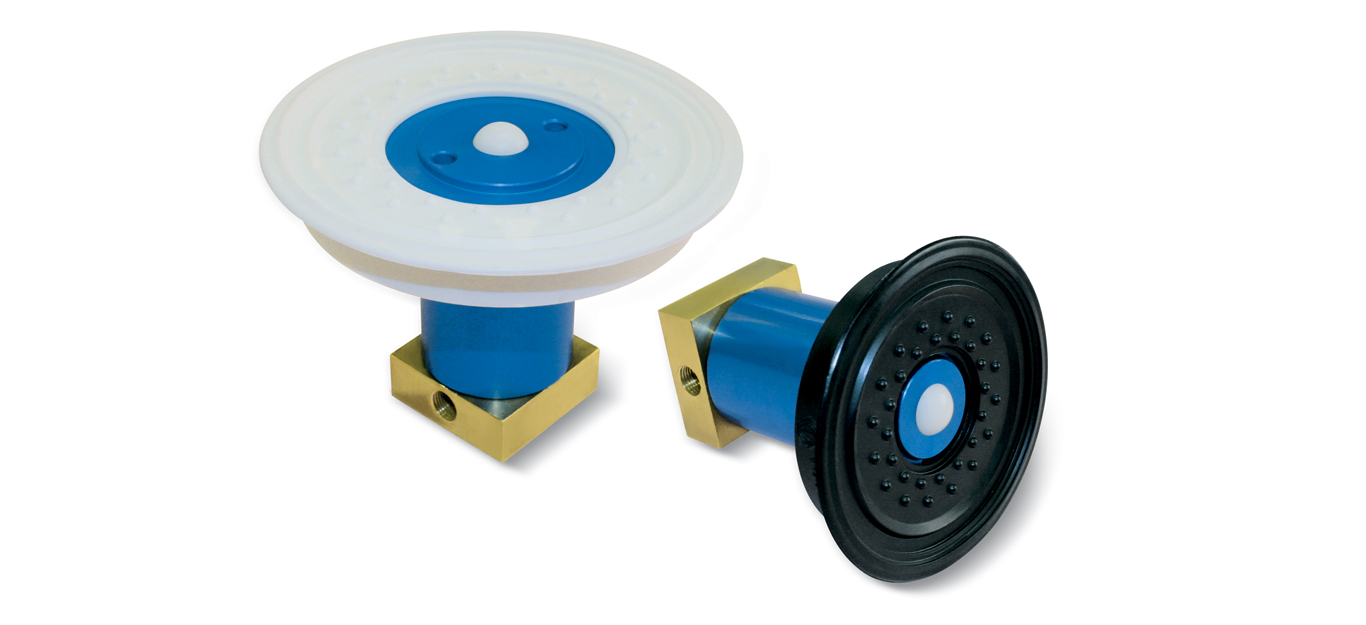

As you can see, panels are placed above a series of Vuototecnica suction cups with ball shutter, integrated in the worktop.

These suction cups are mounted on pneumatic cylinders that raise them above the roller tracks and only operate when the ball shutter valve is squeezed by the panel surface.

Suction cups that aren’t under the wooden panel do not activate. Suction cups that are under the wooden panel, on the other hand, function like clamps and keep the panel firmly in place.

Note in the video how the operator tries to move the panel manually once hooked, without result.

The grip remains firm and secure until the CNC machine has completed contouring or drilling work. Then the suction cups are lowered and the panel is taken away and unloaded thanks to roller conveyors.

The fact that not all the suction cups are activated, but only those that are needed, helps the user not to disperse the vacuum generated by the pump, favouring a more stable grip on the other suction cups in contact with the panel.

The ball valve of these suction cups also prevents dust and machining residues from entering the vacuum circuit. This avoid power loss or blockages.

In addition to these advantages, Vuototecnica also provides, on request, the management of generation and distribution phases, offering customers solutions that allow them to keep the suction cup gripper firm even in the event of power failure or sudden blackouts.

For more information: www.vuototecnica.net