For years now, Vuototecnica has been offering different gripping options to deal with robotic palletizing and depalletizing: single products (suction cups, vacuum generators, valves, etc.) or complete solutions for generation, vacuum management and gripping.

In the video, you can see an ABB robot palletizing plastic containers.

The customer asked Vuototecnica engineers to implement its capabilities.

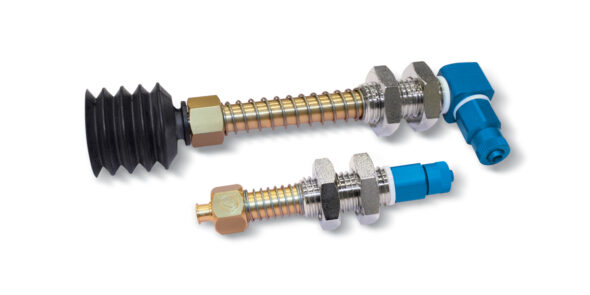

On board the robot gripper, in very little space and in a very simple manner, the customer installed 01 60 10 suction cups, 03 60 10 suction cup holders and PA 100 pneumatic pump.

PA pumps are ideal in terms of capacity and vacuum level for this and other types of applications. They have minimal overall dimensions and do not produce heat or electrostatic charges (very useful features especially in some industrial sectors).

In addition, they save up to 40% of compressed air, have 80% less noise (60-65dB), allow an advantageous ratio between the amount of air consumed and air sucked (or blown).

You can order them in different sizes and weights; even very small ones, as you may have guessed from the video, so that they can be installed directly on the machine.

Finally, you don’t have to think too much about maintenance, in fact a periodic cleaning of the filters is enough.

The entire process and the gripping and release times are managed thanks to a compressed air solenoid valve that supplies the pneumatic pump in an alternating manner.

Vuototecnica suction cups, on the other hand, are available in different compounds and sizes, based on the type of objects to be handled.

If you would like to know which palletisation option is best suited to you, contact Vuototecnica designers at www.vuototecnica.net.