Cheesemaking and milk processing are ancient arts, dating back to the beginning of human civilization, but over time, especially to produce food products with a long shelf life and intact flavor, vacuum technology has come to aid by covering a wide variety of tasks.

Cheese processing steps include, for example, the evaporation of excess water and whey, processes that Vuototecnica vacuum pumps and systems facilitate, without drying out products, as can happen using air, and the compression in containers, another job for which a Vuototecnica vacuum pump can come in handy.

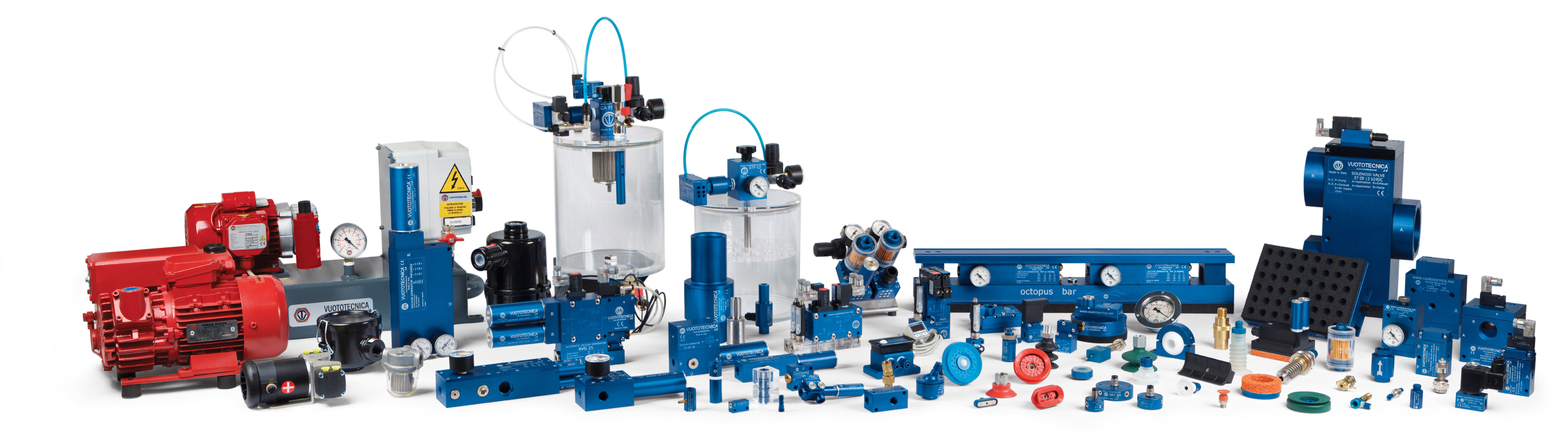

Finally, before landing in large-scale distribution, the dairy products are bagged and sealed. And for packaging, sealing, and transport, vacuum is required: suction cups that move the various pieces without contaminating them or ruining the packages and surfaces, vacuum test systems to check the tightness of the packages, vacuum gripping systems for pallets, and vacuum pumps designed specifically for food use, without the use of oils, and with special care for the production environment, meeting all industry standards.

Vuototecnica is able to follow all stages of cheese production and milk processing and support producers by setting high levels of quality and production speed records with unparalleled care to the product. From suction cups to gripping systems, from pumps to vacuum testing, the catalogue is a rich of opportunities for cheese producers and, in general, for food & beverage field and packaging.

To learn more, you can contact Vuototecnica offices at: www.vuototecnica.net