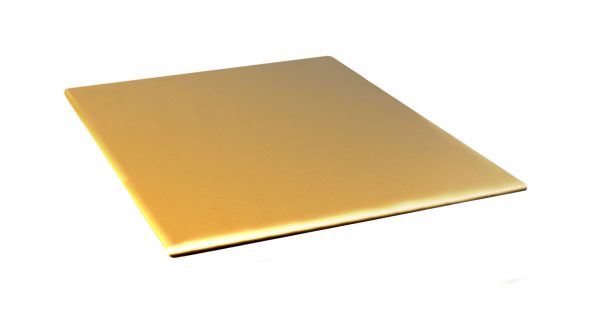

In the jewellery and goldsmithing industry, the gentle handling of materials is essential to avoid damage. This is why Vuototecnica’s Bernoulli vacuum cups are an ideal solution for handling precious metal sheets, such as gold, silver and platinum ones, without the risk of scratches or dents.

This is possible thanks to the Bernoulli principle.

When the BEC is supplied with compressed air, the compressed air flows 360 degrees through the cavity of the central screw, creating a wall effect on the concave surface of the aluminium body. As the speed of the outgoing air increases, the pressure under the BEC suction cup body decreases, thus generating a true lift effect, which allows objects to be lifted and held gently.

It goes without saying that the velvet glove of the vacuum can drastically reduce the risk of scratches and dents on delicate surfaces.

At the same time, however, Bernoulli suction cups provide essential control and precision for all material processing steps.

They are made of anodised aluminium, with the central contrast disk in stainless steel. Antistatic silicone spacers on the gripping surface of the suction cups prevent transverse movements of the object being gripped.

The quick and safe handling of the foils, thus obtained, increases productivity and reduces processing times.

Finally, the versatility of Vuototecnica’s Bernoulli suction cups makes them suitable for various applications, from handling thin metal sheets to porous or micro-perforated products during assembly.

To find out more and view technical specifications, visit www.vuototecnica.net.