We have already discussed of the newest gripping heads made with the 3D printer for single pieces, a solution that allowed us to push even further the possibilities of customization that already Octopus allowed.

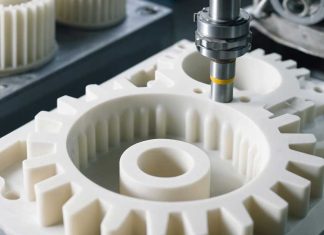

The heads are in fact built ad hoc, in ABS, are lighter and resistant, and the gripping problems can be processed case by case, with ideal gripping heads to accommodate the shape of the object, even to wrap it up.

Let’s see some more details on printing heads and the benefits that this application gives to the final customer.

Let’s see some more details on printing heads and the benefits that this application gives to the final customer.

First of all thanks to this additive manufacturing, we can respond very quickly to the customers needs: gripping hands, with integrated vacuum generation, made in a few days, even faster than the standard method by removal of chips with CNC machines.

In addition, the design imagination has no limits.

The printer used for the realization of these gripping heads, installed at our technical office, uses the FDM technology.

Using the printer at its full capacity, given the success of this new idea, we also thought about putting the printer cartridges in vacuum: the result is a new application, useful to prevent the print material degeneration and to preserve the quality of artifacts produced as a final result.

Using the printer at its full capacity, given the success of this new idea, we also thought about putting the printer cartridges in vacuum: the result is a new application, useful to prevent the print material degeneration and to preserve the quality of artifacts produced as a final result.

Beyond the realization of Octopus vacuum gripping systems, the 3D printer is very versatile for the realization of all prototypes that need to Research and Development department for new vacuum components and also for the creation of small molds from which derive new suction cups.

To learn about the gripping solution that best suits your needs and to customize your applications, please contact the Vuototecnica staff!