The sausages that arrive on our tables go through an elaborated preparation process that consumers usually do not imagine: first the different meats are minced, according to the type of sausage to be produced, and then the spices that give so much flavor are mixed.

During the mincing and mixing procedures, however, it is important to avoid the oxidation of the paste and therefore it becomes fundamental to be able to eliminate air, in order to maintain taste and nutrients in the mixture.

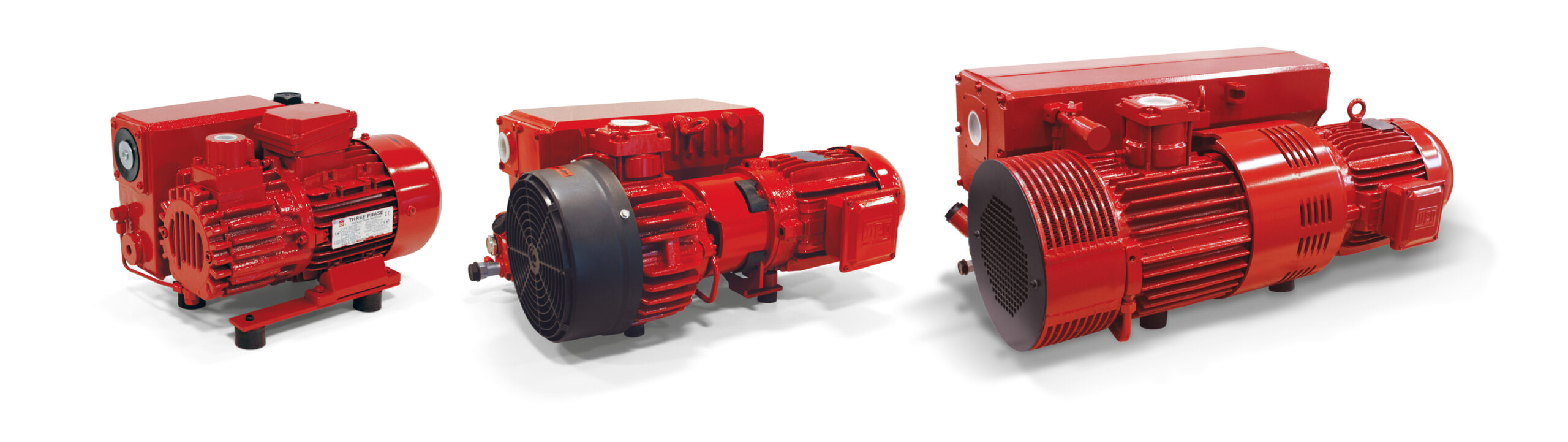

Vacuum can be created for this particular application thanks to Vuototecnica’s RVP rotary vane pumps, which can handle the operatione without cloggging.

In fact, these pumps have a gas ballast valve as standard, with high compatibility with any water vapor that may be present.

The high pumping speed and the reduction of exhaust fumes, thanks to a capacious oil recovery tank, equipped with microfiber de-oiling cartridges, makes them the ideal solution for the food sector.

Moreover, they are compact and suitable for heavy and continuous operation, which is very important in the production of sausages.

RVP pumps comply with the latest European standards (IEC60034) and are equipped as standard with IE2/IE3 energy-efficient electric motors and are made with quality materials, which is why their maintenance is so simple.

Finally, they are quiet and do not overheat during operation, for healthy and efficient working environments.

To learn more and find out which RVP pump model best suits your needs, you can download the catalogue at www.vuototecnica.net