It is often the case that when Vuototecnica designers find themselves renovating existing systems, they have to deal with components such as fittings, filters, and valves for compressed air that are also used for vacuum, indiscriminately, but actually fail to comply with the fundamental parameter of any vacuum system, the vacuum generator’s suction flow rate and pressure differential.

Let us try to understand briefly why this is wrong.

Let’s start with the basic principle that distributing pressurized air (up to 10 bar) is completely different than distributing vacuum (down to -1bar).

By increasing the operating pressure in a pneumatic circuit for compressed air, we can safely increase the volumetric flow rate for the same section of pipe we use.

Distributing vacuum is completely different because, by increasing the degree of vacuum, the volumetric suction flow rate drops dramatically to zero.

Hence the extreme importance in vacuum, of using components that respect the cross-sectional area of the vacuum pump’s suction port and its flow capacity at atmospheric pressure.

Hoses for compressed air can also be used for small suction sections (6-8mm inner tube diameter), but above these sections the pipe tends to collapse and implode for lack of a spiral reinforcing core to counteract atmospheric pressure.

In addition, quick couplings for compressed air are born and tested to ensure the tightness of a pipe that expands under the effect of pressure and not a pipe that tends to collapse and implode under the effect of vacuum. This is where the flow losses and leaks of pneumatic fittings come from.

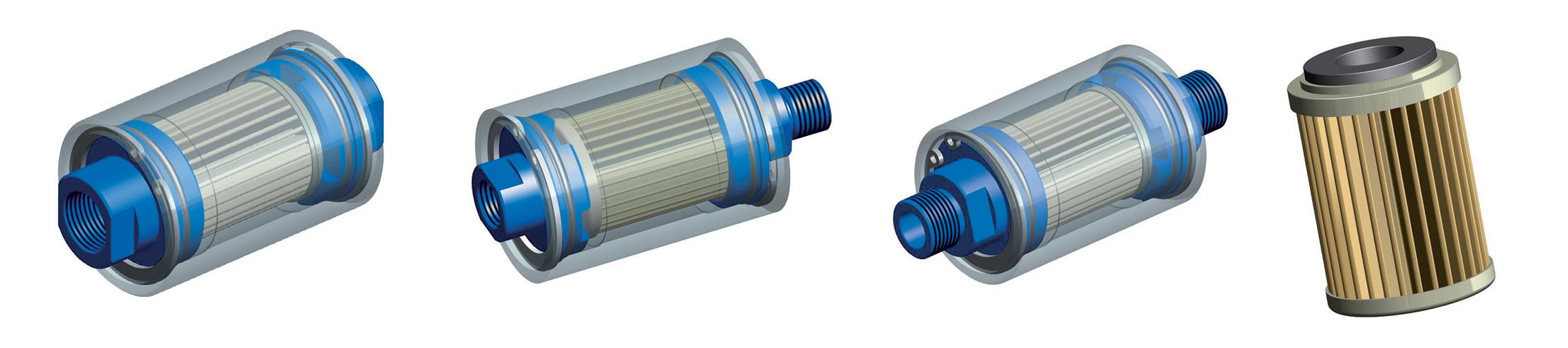

The same constitutive reasoning applies to compressed air filters, which generally have filter cartridges made of porous polyethylene or sintered material.

Materials that are excellent for filtering a flow of compressed air at 6-8 bar pressure but real bottlenecks in the suction flow rate of a vacuum pump.

Not to mention the compressed air solenoid valves used to manage the opening and closing of the vacuum on handling equipment with suction cups.

Several times in our blog, we have pointed out the substantial and functional difference of our vacuum solenoid valves, which were born precisely to guarantee the flow rate of the vacuum sources connected to them precisely by virtue of an internal mechanics and a stroke of the sealing pads that is significantly superior to any compressed air valve of the same nominal section.

Without going into technicalities, for which we invite you to contact the offices of Vuototecnica, it is normal to try to reuse the same pneumatic component if it is suitable for the purpose but we must be aware that we hardly have the same efficiency as a component created exclusively for vacuum.

Vuototecnica, has been making components specifically for the exclusive management and distribution of vacuum for almost 50 years.

Piping, fittings, filters and solenoid valves designed specifically to maximize vacuum performance in a vacuum circuit.

Each application is specific and it is worthwhile in every case to rely on the assistance of an expert.

Read more: www.vuototecnica.net