In the competitive industrial sector, where efficiency and innovation are crucial for success, Vuototecnica’s Star Vacuum (SV) suction cups shine brightly.

Their unique star-shaped design, with integrated rubber reinforcement sectors, combines a soft, flexible gripping lip with a rigid and stable support surface. This configuration ensures a secure and deformation-free grip on flat and flexible objects, such as layers of cardboard or thin metal sheets, in both vertical and horizontal orientations.

The versatility of the SV suction cups is another strength; they can be easily integrated into various industrial systems thanks to their anodized aluminum metal mounting supports, available with both male and female threads.

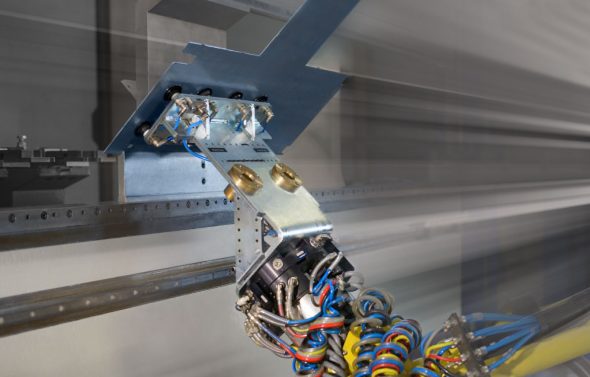

Alongside the SV suction cups, Vuototecnica offers the MSVE multifunction vacuum generators, ideal for applications in the sheet metal sector. These compact and lightweight generators are designed for operating suction cup systems, ensuring high performance even in limited spaces.

When equipped with an Energy Saving cable, the micro solenoid valve for compressed air supply activates, and the MSVE generator creates the necessary vacuum for the suction cups. Once the set vacuum level is reached, the vacuum switch intervenes, deactivating the micro solenoid valve and stopping the flow of compressed air. The supply is restored only when the vacuum level falls below the set minimum, thus maintaining the vacuum within the safe operating parameters of the suction cups and significantly reducing compressed air consumption.

MSVE generators are also effective in their details: operating at a pressure of only 3.5-4 bar, they achieve vacuum levels of -85/-90Kpa and are available in various suction capacities.

The adjustable backflow feature, another exclusive characteristic developed through a valve inside the ejector with a screw flow regulator, allows for the rapid release of the suction cups and the cleaning of the pipes, facilitating operations without damaging the gripping lip. Unmatched in the market in terms of capacity, it also allows the suction cups to slide (without damaging the gripping lip) during the repositioning phase of the robotic gripper involved.

All of the above translates, in the sheet metal sector, into excellent sealing and minimal operating costs, as the operation of the MSVE is limited to the strictly necessary time for evacuating the suction cups that handle sheets.

Furthermore, MSVE generators prevent waste and load losses thanks to the check valve, which ensures the maintenance of the vacuum even in the absence of electrical power.

The teamwork between the Star Vacuum suction cups and MSVE vacuum generators offers a complete solution for the safe handling of materials in the sheet metal sector, while also ensuring significant energy savings.

To learn more about these technologies, visit www.vuototecnica.net.